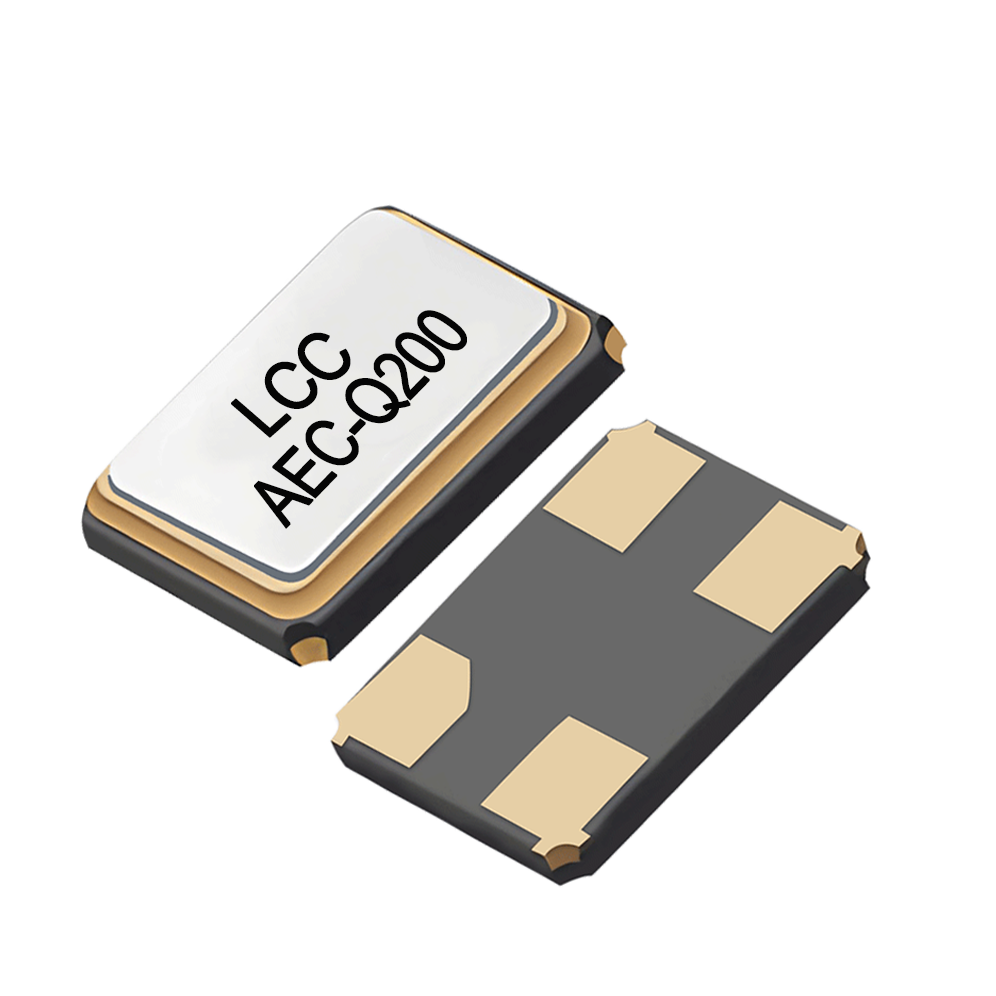

Differences in Working Environments between Automotive-Grade and Consumer-Grade Crystal Oscillators

Automotive-grade and consumer-grade crystal oscillators have significant differences in design, performance, reliability, etc., mainly due to the varying degrees of harshness in their application scenarios. The following are the differences in requirements for the working environments of automotive-grade and consumer-grade crystal oscillators.

1. Working Environment Requirements

Automotive-Grade Crystal Oscillators

Temperature Range: They need to support extreme temperatures (such as -40°C to +125°C) to adapt to environments like the engine compartment or cold regions.

Vibration/Shock Resistance: They must pass high-intensity vibration tests (such as 20G vibration) to ensure stable operation on bumpy road conditions.

Humidity/Corrosion Resistance: They need to withstand harsh environments with high humidity and salt spray (such as corrosion in coastal areas or due to de-icing salts in winter).

EMC Immunity: They have higher requirements for electromagnetic compatibility to avoid signal interference among in-vehicle electronic devices.

Consumer-Grade Crystal Oscillators

Temperature Range: Usually, it is 0°C to +70°C, suitable for indoor devices (such as mobile phones and computers).

Vibration/Shock: They only need to meet the conditions of daily use (such as minor collisions or drops of handheld devices).

Environmental Adaptability: There are no special requirements for anti-corrosion or high humidity.

In conclusion, automotive-grade crystal oscillators have stricter requirements than consumer-grade crystal oscillators in terms of temperature, vibration/shock resistance, humidity/corrosion resistance, and EMC immunity.